Upholding the Quality standards for Fortified Rice Kernels and Fortified Rice .

Prevalence of malnutrition in IndiaThe double burden of malnutrition i.e., the coexistence of undernutrition and overnutrition, is a major public health challenge for many countries globally, including India. According to the findings of the National Family Health Survey (NFHS)-5, 18.7 % of women in India are underweight i.e., they have a BMI less than 18.5 kg/m2, and 24 % of Indian women are either overweight or obese i.e., they have a BMI above 25 kg/m2. More than 50 % of children and women are anemic. The NFHS report also captures data on the prevalence of diabetes and hypertension in India, and it indicates the growing risk of these lifestyle diseases in India. To address these public health concerns, it is important that appropriate nutrition-specific, and nutrition-sensitive interventions are planned on a large scale.

- Combating Micronutrient Malnutrition through Food Fortification

Public health solutions such as diet diversification, food fortification, and micronutrient supplementation can significantly reduce the prevalence of micronutrient deficiencies in India. Food fortification is a high-impact solution to prevent, reduce, and control the prevalence of micronutrient deficiencies. It is a cost-effective strategy that can improve the nutrition status of all population groups in India.

#HexagonNutrition is a leader in global health innovation and is at the forefront of implementing effective approaches to boost and enhance rice fortification worldwide. It caters to the micronutrient premix requirements to produce FRK using both hot & cold extrusion processes. Hexagon Nutrition is a preferred partner for many renowned multinational fortified rice brands, governments, and international NGOs globally.

As an organization producing high-quality Micronutrient Premixes, using scientifically proven methods, we follow the following practices to ensure the production of high-quality fortified rice kernels.

- Process the raw materials for FRK in the right way

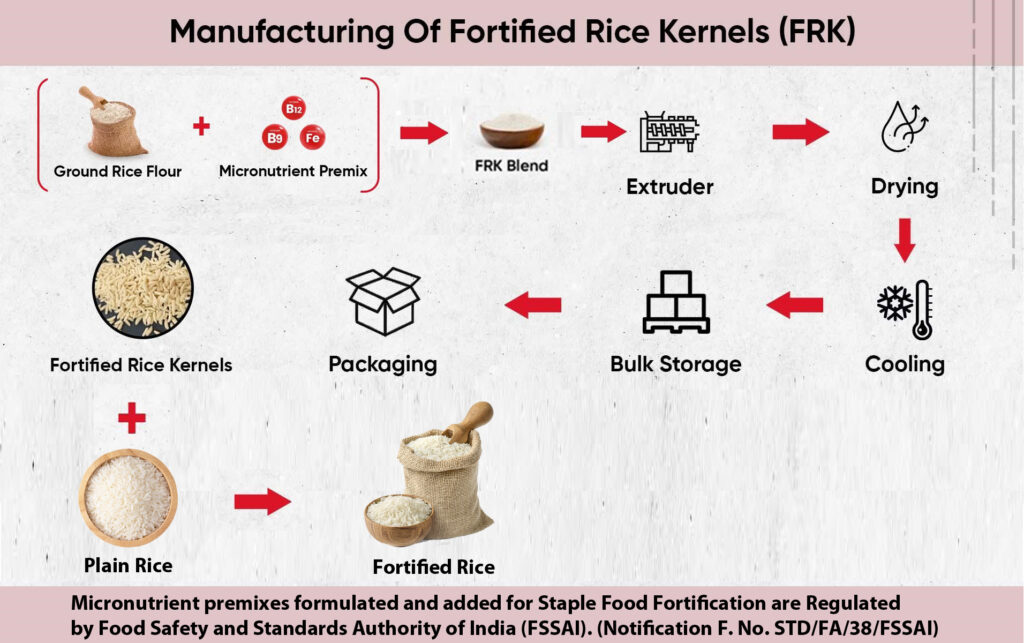

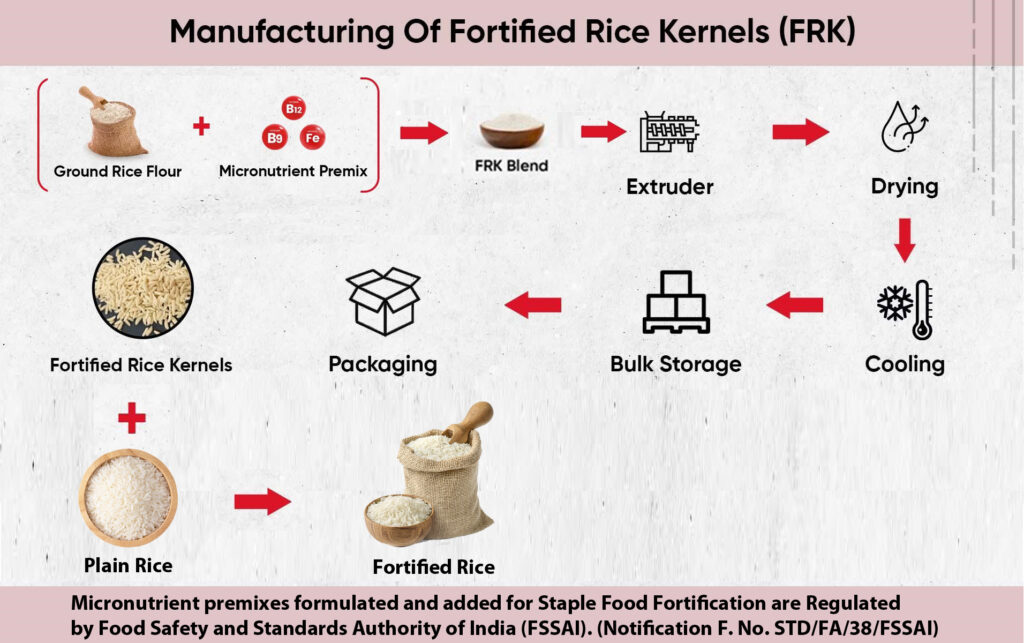

- Rice, used to prepare FRK have an initial moisture content of 11- 12%. The flour is ground using a 30-60 mesh sieve.

- Food grade Vitamin and Mineral premix used to prepare FRK is as per the prescribed Food Safety Standards (Fortification of Food) Regulations, 2016

- HN follows FSSAI’s standardized ratio for Micronutrient Premix

- FRK are blended with traditional rice in ratio between 1:50 to 1:200 (Notification F. No. STD/FA/38/FSSAI)

We follow the recommended blending ratio

- Mix 10g of FRK with 1 kg of regular rice. Thus, 1 kg of fortified rice produced using this ratio, contains- 28 mg-42.5 mg of iron, 75-125 micrograms of Folic Acid, and 0.75-1.25 micrograms of Vitamin B12.

- Homogenised mixing of Rice

Homogeneously fortified rice is produced by feeding the rice in a 1:99 w/w ratio to the blender, FRK blended with traditional rice in ratios between 1:50 to 1:200

- Should Have an appropriate Quality Control plan Ensure routine quality assessments before the fortified rice stock is distributed in the market and consumed by the masses.